#03 | REEs recovery from acidic mine water

By Óscar Crespo, Mehrez Hermassi, Julio López, Oriol Gibert and José L. Cortina (UPC)

and by Sergio Carrero and Jordi Cama (IDAEA-CSIC)

Efficient management of metal-contaminated acid waters generated from abandoned open pits during prolonged periods of inactivity has become imperative nowadays. The perspective of new regulations on sulphate and metals discharge limits and an increasing market dependence on critical raw materials availability demand a change of paradigm in the mining sector to a more circular model. In this context, valuable by-products such as metal sulphides, rare earth elements (REEs), purified water and acid can be recovered, wastewater discharge can be minimized, and the amount of sludge disposed into landfills can be reduced.

These needs are currently investigated by the Politechnical University of Catalonia (UPC) and the Institute of Environmental Assessment and water Research (IDAEA-CSIC). These institutions have been working together with industrial customers exploring sustainable solutions. At the moment, recovery of REE is performed via REE- oxalate precipitation. The overall process consists of two consecutive steps. In the first one, ion exchangers with selective sorbents are used to separate heavy REEs (HREEs) and light REEs (LREEs). In the second step, REEs are recovered from the resulting eluents via precipitation using oxalic acid to produce REE-oxalates (REE2 (C2O4)3 ).

Important goals of this research are to meet the optimal conditions that enable us an increase in the purity of the REE precipitates and an improvement of the REE recovery efficiency and the separation factor for heavy REEs (HREEs) and light REEs (LREEs). Results show that:

- A two-fold increase in the stoichiometric ratio of the amount of oxalic acid improves the precipitation process

- A fast addition of oxalic acid results in a high efficiency in REE precipitation

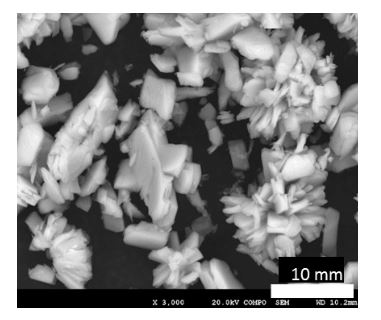

- The retrieved REE2 (C2O4)3 precipitate exhibits a well-defined crystal morphology (Figure 1). Further research is being focused on the achievement of higher HREE and LREE separation and maximum REE yield.

More news

Discover the results of REECOVERY in its final video

REECOVERY has published its final video, in which you will be able to learn about the REECOVERY solution and discover... View Article

REECOVERY comes to an end after succeeding in recovering critical raw materials from water in the mining industry

The European REECOVERY project, which over three years has developed and validated a system for recovering critical raw materials such as... View Article

New papers published in the context of the REECOVERY project

Alexandra Roa, PhD Student at UPC, together with Julio López and Jose Luis Cortina, Researcher and Chemical Engineering Professor at... View Article